Wide band power detector to control microwave

station

by Philippe Borghini /

F5jwf

April 19th 2010

Introduction

Everyone knows the famous logarithmic detectors from

Analog Device. So many designs have been done with the well

known AD8307. These

kinds of circuits provide a dc voltage proportional to the RF signal expressed

in dB. Analog

Device expands recently his detector family with the ADL5519 which is still

usable at 10GHz.

The assembly presented below integrates a dual channel

power probe by using the ADL5519. This design provides a control unit to

measure the output power of microwave radio station. His enhanced linearity

makes it also valuable as a good alternative to the old HP432 RF power probe to

any Ham microwave labs.

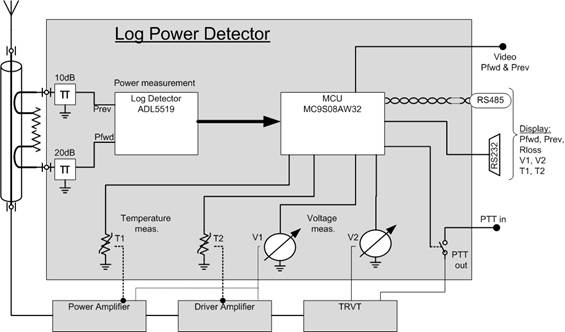

Block Diagram

The particular interest of the ADL5519 is focused on

bandwidth which is specified up to 8GHz (but still usable in 10GHz with reduced

dynamic). With two channels, it is possible to measure the power transmitted to

the antenna and the reflected wave, to calculate the return loss and block the

PTT when problems arise. As I originally destined it to my EME 13cm station the

module is controlled remotely by serial interface (RS232 and RS485) to be

installed in the antenna 30m away the shack. A simple RS232 VT100 terminal

allows the full control of the assembly as the whole software is embedded.

The set also includes some additional features such as

measuring the temperature of the PA with KTY probes and power supply voltages.

Figure 1: Block diagram of DetLog

module. Logarithmic detector and Micro Controller Unit (MCU).

Figure 1: Block diagram of DetLog

module. Logarithmic detector and Micro Controller Unit (MCU).

The RF coupler remains external to the detector and

can be done either with semi rigid coaxial cable or with commercial device. The

coupling factor is taken into account by the software and can also be included

in the calibration process.

Typical

Applications of the DetLog board

Control of 13cm F5jwf EME station

Linearity and dynamic

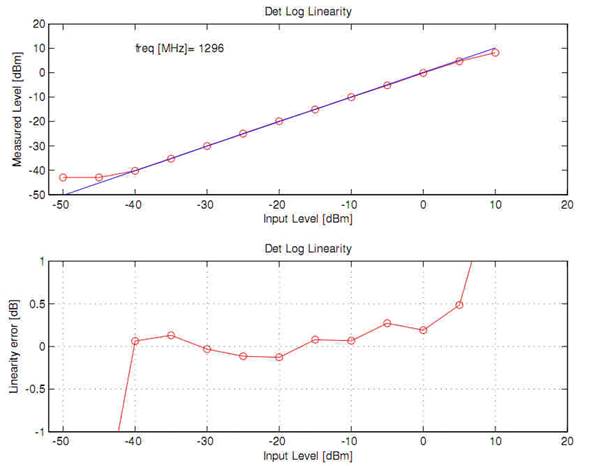

Without calibration, the linearity of the ADL5519 is

already excellent. The frequency behavior is also fairly flat but a calibration

specific to each frequency can improved a little bit the linearity. The dynamic

is around 50dB for an accuracy of +/- 0.5dB. Isolation between two channels is

better than 40dB.

Figure 2 shows the ultimate accuracy obtained at 1296MHz +

/ - 0.1dB over nearly 40dB.

Figure 2: Linearity at 1296MHz.

The curves for other frequencies are quite similar:

Up to 8GHz, the dynamic of 50dB is guaranteed. Above

this frequency the sensitivity decreases and more power is needed for the same

detected voltage. The linearity is also a little bit degraded but the detector

is still usable as PA controller.

The input impedance of the detector chip is equivalent

to 2kOhms load in parallel with 0.6pF. Loaded with a resistance of 50 ohms on

the input, we obtain acceptable impedance up to 2 GHz but degrade rapidly

beyond. The input attenuation pad can significantly improve the return loss and

the broadband performance. The layout has two

10dB pad achieved with 0402 SMD resistors. These pads can shift up the dynamic

to 10 or 20dB increasing the compression point respectively to 10dBm or 20dBm. Obviously

this comes at the expense of sensitivity.

It is advisable to have at

least 10dB to ensure a good matching of the input. The maximum power rating of

10dB attenuator made with 0402 SMD resistor is around 100mW, beyond an external

attenuator must be added.

An optimum configuration in terms of dynamic and sensitivity for return loss measurement is 20dB attenuation on the forward channel and 10dB on reverse channel. This option gives the following dynamics:

Channel

Forward: Dynamic~ -30dBm…+20dBm S11~ < -23dB for f=144M...10GHz

Channel

Reverse: Dynamic~ -40dBm…+10dBm S11~ < -20dB for f=144M...10GHz

Note: 10dB attenuation seems to be an optimum of flatness for an attenuator

in PI with regular SMD package. This value corresponds to resistances value

between 70 and 100 ohms. Outside these limits the behavior of capacitive or

inductive SMD package dominates and introduces resonances.

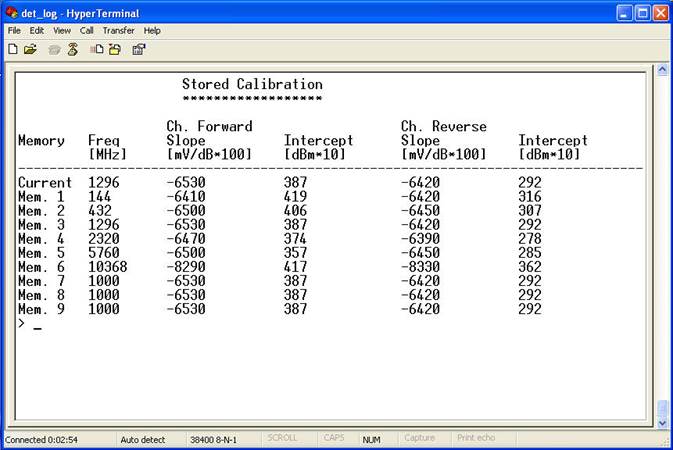

Calibration

The calibration process is the action of

putting a well known level at the RF input and entry

this level to the microcontroller to correct the measurement error. Of course

few points are necessary to obtain good correction and those are frequency dependant. The calibration algorithm finds then the best

linear regression minimizing the error over the full dynamic. This process is done by an external test bench based

on RF synthesizer and commercial power meter, taking about 50 points Vdetected = f (Pin), and calculating the gain and offset

for each frequency. These values are then stored in

Basically for the kit proposed below two calibration are possible:

. Default standard cal (kit#1 and kit#2) accuracy around typ. +/-0.5dB up to 1.2G and typ +/- 1dB for higher freq.

. Calibration dedicated to the DetLog board mounted and tested only possible on kit#3. Then the accuracy is around +/- 0.2dB

Remark:

The calibration algorithm does not work

on the frequency axis. It means that between two calibrated frequencies no

correction is done.

Example: If you want to measure at 3400

MHz you have to use the closer cal, let say 2320 MHz

and then correction is not optimal.

You could run the built in calibration

process at 3400 MHz to calculate the linearization parameters at this frequency

and save it on one free memory.

The built in cal

use up to 8 measurements points to calculate the linearization. This procedure

can also be used to take into account external

attenuator or coupling factor. At the end of the process the cal parameters are saved into the current cal memory which is located in ROM (no volatile after power

off). A total of 9 memory banks are

available to save calibration for further uses.

Figure 3: The calibration factors for one specific frequency can be reloaded with the VT100 terminal

A simple offset to the

displayed value is also configurable to take into account such as a directional

coupler factor or an external attenuator.

Voltage and temperature measurements

The DetLog PCB measures also voltages and temperatures

of power amplifier. Two channels are available:

.

Voltage 1: Resistif divider 1:7.8 Input= 0…40Vdc

.

Voltage 2: Resistif divider 1:7.8 Input= 0…40Vdc

.

Temp 1: KTY-10-6

temperature sensor Temp=-20…100°C

.

Temp2: KTY-10-6

temperature sensor Temp=-20…100°C

A PWM (Pulse Width Modulation) output can be connected to

control the speed of the FAN. The speed is controlled by the software according

to the temperature Temp1.

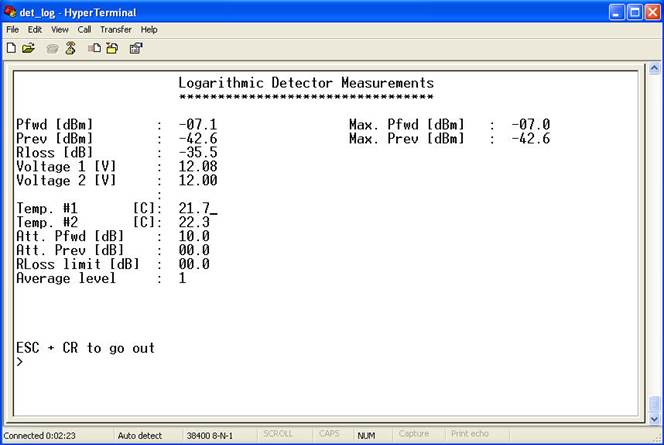

VT100 User Interface

Measurements of power, temperature and voltage are

displayed directly on the terminal screen (VT100 emulation commonly available

under any OS). The different functions are handled by the terminal and are

summarized in the on-line Help. The Return Loss limit for example is configured

with the terminal. Above this configured level the module open a relay to block

the PTT.

Figure 4: Main page on the RS232 terminal. Current and "max. hold" power is displayed in dBm. PA voltages and temperatures. The display is refreshed

every 100ms.

Video outputs

Two analog outputs (one for each channel) giving an

exact replica of the measured power is available as a DC signal varying from 0 ...

5V for the total detector dynamic. They can drive analog meter or external XY

plotter.

The RS232 port can also be used for automatic measurement

bench and power points can be transferred in third-party software.

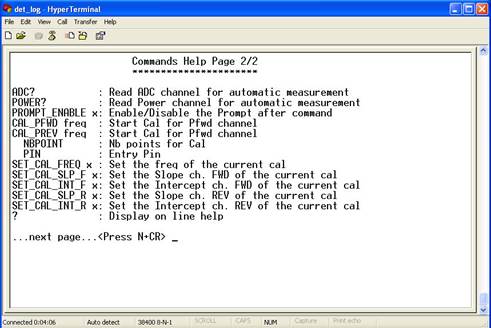

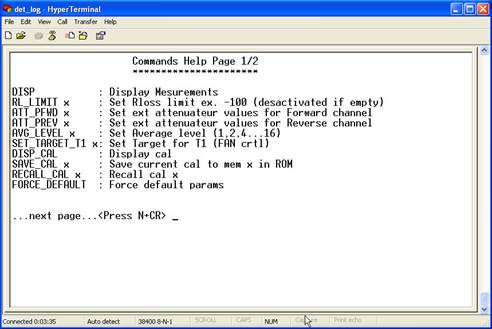

VT100 Commands descriptions

The built in help is access on the RS232 port by typing

?. The Figure 5 and Figure 6 are then displayed.

Figure 5: Online help is displayed on the VT100 terminal with the ? command.

Figure 6: Page 2 of the help.

Figure 6: Page 2 of the help.

List of

the command

Note 1: All command are NOT case sensitive, they can be either upper or lower case independently.

Note 2: The format to entry attenuation in dB (or power level in dBm) is on 3 digits without decimal point.

Example: To entry the attenuation value of -12.5dBm you have to entry -125

|

Command |

Explanation |

Example |

|

DISP |

Display the main panel with the measurement. Escape and carriage return allows to go out of this page. |

|

|

RL_LIMIT x |

Set the Return loss limit. If the measured Return loss exceed this value the micro relay open which block the PTT of the station. |

x = -85 for RL max of -8.5dB. If measured RL is -5dB, the PTT will be blocked to protect the PA. |

|

ATT_PFWD x |

Set the value of the external attenuator for forward channel. Negative value represents attenuation. |

x = -100 for external attenuator of -10.0dB |

|

ATT_PREV x |

Set the value of the external attenuator for reverse channel. Negative value represents attenuation. |

x = -100 for external attenuator of -10.0dB |

|

AVG_LEVEL x |

Set the value averaging. When measurements are close to the noise, average can be increase to higher value to improve measurement confidence. |

x =1, 2, 4, 8, 16 |

|

SET_TARGET_T1 x |

Set the temperature limit for temp1. When the temperature measured by the probe temp1 will come close to this limit, the controller will increased the speed of the PA fan by increasing the duty cycle of the PWM. |

x =430 for a temperature limit of 43°C |

|

DISP_CAL |

Display the calibration table. |

Cf. Figure 3 |

|

SAVE_CAL x |

Save the current calibration into memory bank x. |

x=1…9 |

|

RECALL_CAL x |

Recall the calibration of memory bank x into current cal. |

x=1…9 |

|

FORCE_DEFAULT |

Set all variable of the controller to factory settings. Could be useful when bad parameters have been entry. Following this command, the factory standard cal is reloaded and custom cal lost. |

|

|

ADC? |

Request to get the ADC value (10bits) of the RF detector. The result is express in microvolt. |

Vdet_Pfwd=4562000 Vdet_Prev=2350000 |

|

POWER? |

Request to get the measured power of both channels. The result is express in dBm *10. The command can be used in automatic test setup to read the power level. |

Pfwd=-245 Prev=-372 |

|

PROMPT_ENABLE x |

In normal situation, the controller answer to each command with a prompt symbol which is >. During automatic measurement when the module is pooled by tiers party software, disabling the prompt avoid complicated ASCII stream handling. With x=0 the prompt is not send anymore. |

X=0 or 1 |

|

CAL_PFWD freq |

Start the build in user calibration process. The software expect that you connect RF source and you entry the power level. |

CAL_PFWD 1296 |

|

NB_POINT x |

This command works with the previous "CAL_PFWD freq" command and allows to entry how many points is used for the calibration. The maximum points for the built in cal in 8. |

NB_POINT 4 |

|

PIN x |

This command works with the previous "CAL_PFWD freq" command and allows to entry the value of the power level you just connect to the input port. The maximum dynamic is -70dBm…+20dBm. Remember that the format for level must comply with Note 2 |

PIN -200 (for -20.0dBm) |

|

CAL_PREV freq |

Same command as CAL_PFWD freq for the channel reverse. |

CAL_PREV 1296 |

|

SET_CAL_FREQ x |

Allows to entry the frequency for the current cal. |

SET_CAL_FREQ 1296 |

|

SET_CAL_SLP_F x |

Allows to entry the cal SLOPE cal parameter for the current cal. It is expressed in dB/mV *100 as shown in Figure 3. |

SET_CAL_SLP_F -6472 |

|

SET_CAL_INT_F x |

Allows to entry the cal INTERCEPT cal parameter for the current cal. It is expressed in dBm *10 as shown in Figure 3 |

SET_CAL_INT_F -395 |

|

SET_CAL_SLP_R x |

Same as SET_CAL_SLP_F x for reverse channel. |

SET_CAL_SLP_R -6472 |

|

SET_CAL_INT_R x |

Same as SET_CAL_INT_F x for reverse channel. |

SET_CAL_INT_R -395 |

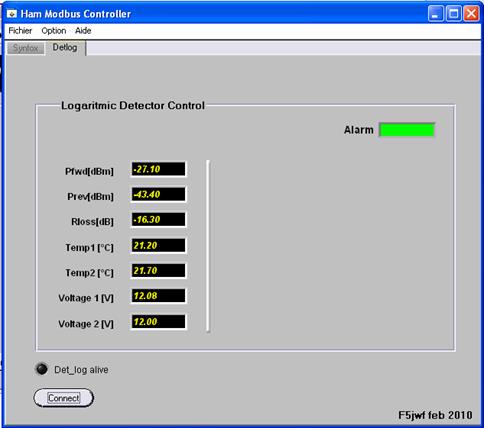

RS485 Bus

Since few developments, F1TJJ and I start to

implement RS485 communication between our HAM radio modules. As this two wires

protocol is differential it allows transmitting easily few ten of kbps over

very long twisted pairs. Stephane also implement the MODBUS (protocol level 2)

which run over the rs485. This solution provide a frame oriented communication

with error detection and device addressing over the bus.

Since few developments, F1TJJ and I start to

implement RS485 communication between our HAM radio modules. As this two wires

protocol is differential it allows transmitting easily few ten of kbps over

very long twisted pairs. Stephane also implement the MODBUS (protocol level 2)

which run over the rs485. This solution provide a frame oriented communication

with error detection and device addressing over the bus.

To keep simple,

the DetLog module just attached itself on this two

wire and can be remotely controlled by using a small piece of software running

on windows XP.

Figure

7: Windows XP HAM

Modbus Controller application

Design and Layout

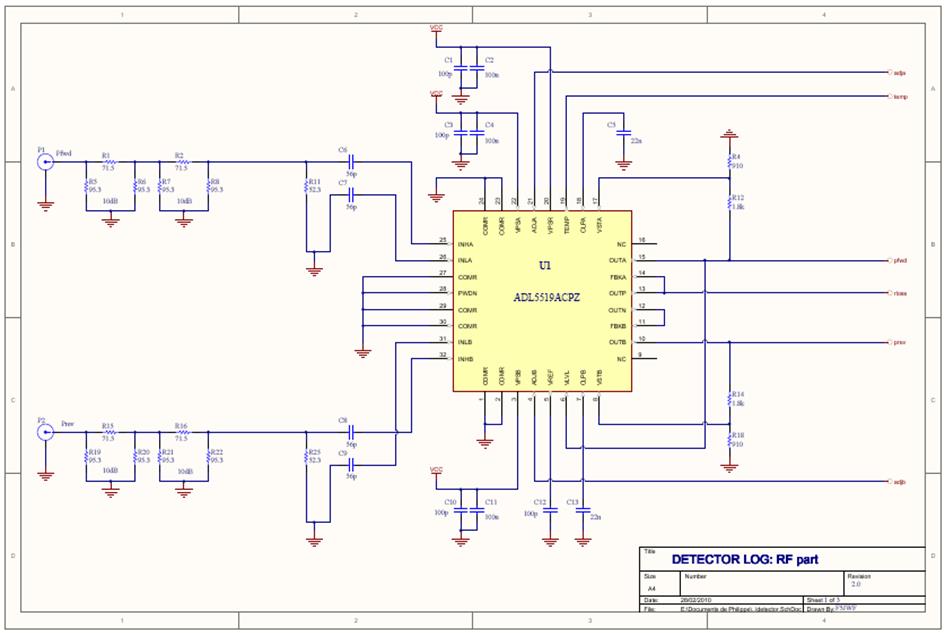

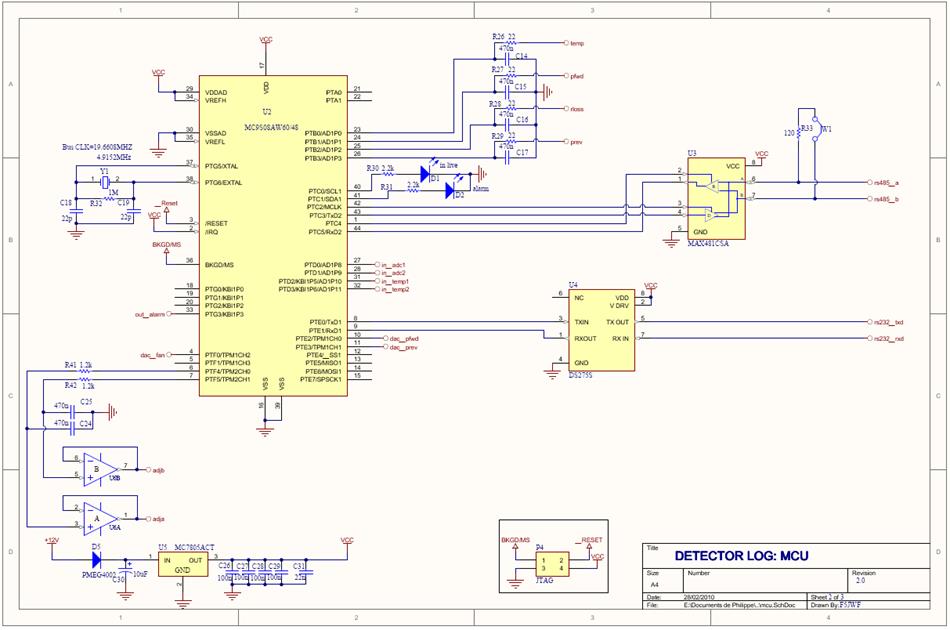

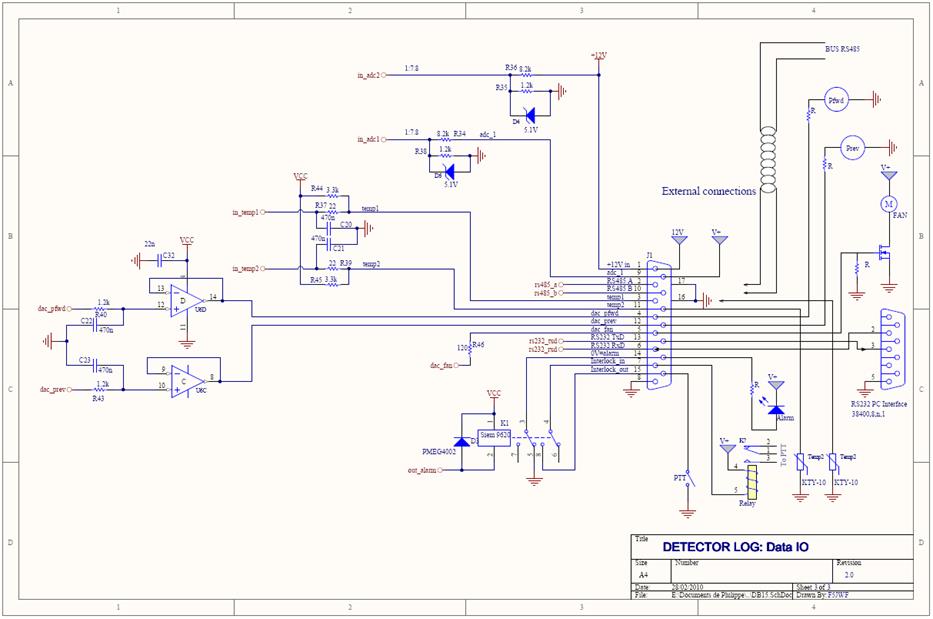

The schematic of the module is shown on the Figure 7 to Figure 9. It is a very standard application of the detector and of the MCU devices and nothing special has to be said. Only a few additional circuits allow interfacing with outside world. The module is powered with a single 12V dc power source.

Remark: These figures here below give an overview to present the module. To be sure to have the up to date version use the pdf design folder

Figure 8: Schematic part 1: Detector with 10dB attenuator pad.

Figure 9: Schematic part 2: MCU with serial interfaces RS232 and RS485

Figure 10: Schematic part 3: Interface components. Standard DB15 connector is used for control signals. On the right of the DB15 the external component (KTY temp. probe, PTT relay,…) can be seen.

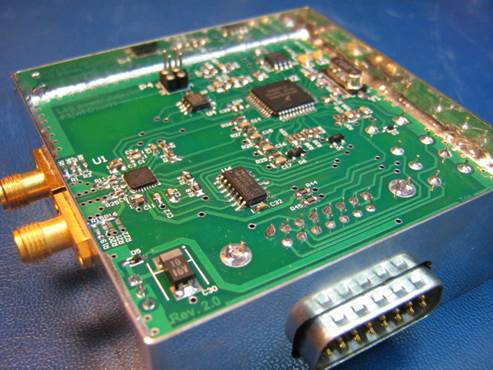

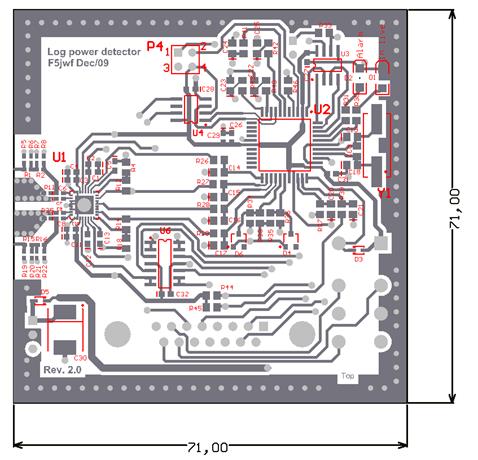

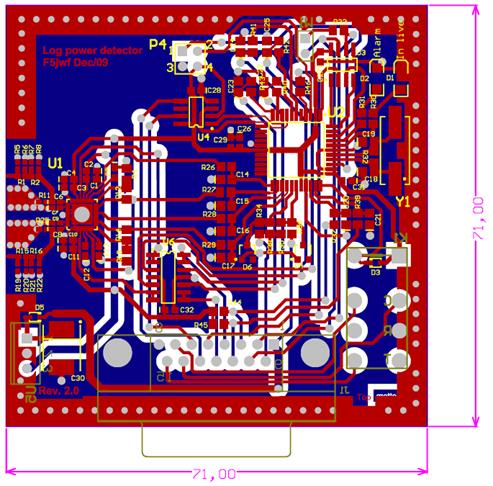

The layout is done on printed circuit board

FR4 double sided plated holes of 0.8mm with serigraphy on both side. The PCB

can be soldered in a standard 74x74 Schubert box. Most

components are SMD 0805, 0603 and 0402 for input attenuators.

Figure 11: Two side PCB Layout. TOP layer in red and Bottom in blue. Figure 12: Component view. Almost all parts are soldered in the TOP layer.

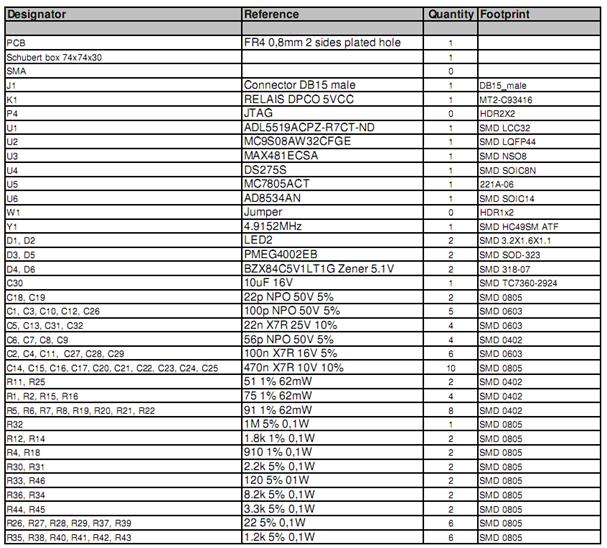

Bill of

Material

Document up to

date ready for download

Download the Up to date Design Folder in pdf

Configuration file for Windows Hyperterminal

Mounting guidelines

All parts are SMD, they have to be soldered carefully but this kit is definitely within the reach of any HAM radio who is experienced with assembly in the RF and microwave band. The most sensitive step is the soldering of the detector ADL5519. The best practice from my experience is to use SMD solder paste and heat up with hot gun. The chip is then auto centered into the pad and is magically done. The details of the mounting are explained in the design folder above. The following video give an idea how to deal with this step.

Soldering of the ADL5519 (35MB)

Conclusions

In terms of dynamics and accuracy, this detector is a

good alternative at affordable price of most sensors available at flea markets.

The DetLog board provides

functionalities which can be used in a lot of application like power amplifier

control, labs power measurement, antenna gain measurement with competitive

accuracy. It can be easily interfaced trough serial interface for automatic

test bench.

A big part of my time in this development has been used

for software design, I really want to thanks Stéphane

F1TJJ (http://www.ham-hyper.com/) for his great

support during this phase.

Kit availability

I have organized myself to propose the following kits:

|

Kit#1: PCB and

special parts |

|

Price 40 euros |

|

PCB , microcontroller MC9S08AW32 programmed with standard

calibration, Detector ADL5519 |

||

|

Kit#2: Kit with all

parts |

|

Price 90 euros |

|

PCB, microcontroller MC9S08AW32 programmed with

standard calibration, Detector ADL5519, all parts according to the BOM,

including drilled Schubert box but except the two input SMA connectors. |

||

|

Kit#3: Fully

assembled and tested |

|

Price 250 euros |

|

Detector box fully assembled, tested calibrated

(accurate cal). Each module is calibrated and

delivered with calibration sheet. |

||

Those kits can be ordered to my email address:

![]()